dempseyprec

SBGuidance AutoPlough

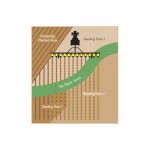

Straight and smooth surfaced ploughing isn’t only a pretty sight, but the best preparation for the new season. A smooth seed-bed makes sure every plant has the perfect start at the same time. A level seedbed ensures a uniform emergence and thus makes weed control easier and more successful, especially hoeing for organic farmers. AutoPlough makes ploughing a less demanding job.

Fewer problems due to different kinds of soil and slope changes, and no more fighting the plough through tough spots, or running on turned land to straighten your mark. AutoPlough adjusts the plough width cylinder and keeps it continually on the required width. AutoPlough will automatically widen and narrow the plough to cancel out any deviations from a straight furrow in every circumstance. This provides fewer changes in traction, more constant ploughing depth which means saving fuel, and a consistent, level finish. AutoPlough is a useful expansion of your SBGuidance Auto steering system. Experience has proved that machine auto steer works more effectively during spring cultivations when the driving lines are exactly the same as the plough lines. Implement deviation will be reduced appreciably.

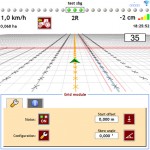

AutoPlough is operated through the GeoSTAR 250 display making it easy to use. During ploughing all necessary information is shown in one screen. Settings such as working width, steering speed and steering boundaries are readily adjustable. The system can then measure the off-track distance, process it, and adjust the plough width accordingly. It is even possible to plough wedged or curved fields. AutoPlough is brand independent and easy to install. The plough width is adjusted by the existing plough width cylinder. The cylinder is operated by an electro-hydraulic valve or by using one of the tractor’s electro-hydraulic valves. (Fendt, John Deere, Valtra). For ease of operation additional optional sensors can be mounted to automate (dis)engagement of the system.

Unique advantages

- Straight and level ploughing optimizes all of the following operations

- Full control via the GeoSTAR 250 display

- Perfect ploughing on curves and wedges

For more information, demo’s, pricing or advice regarding any of our products or services please

SBGuidance Twin Disc

The SBGuidance TWIN version with disc coulters is often the best choice to steer an implement.

SBG has extensive experience with this type of steering and can legitimately be called a specialist in this area.The entire disk steering has been extensively proven in practice. The disc coulters are available in two different sizes, normal (Ø 45 cm) and XL (Ø 60 cm).

Depending on the size and type of implement, one or more discs coulters are installed behind the implement. For light drills and implements one disc coulter is often sufficient. Heavier and larger machines require two or more steering discs, that are connected by means of a rod. For folding implements the rod is replaced by two interconnected hydraulic cylinders.

Excellent on hillsides

TWIN-Disc prevents drifting of the implement. As a result tractor and implement are no longer offset, but remain perfectly aligned and repeated operations will fit perfectly.

The hydraulic obstacle protection enables the steering discs to retract whenever it hits a stone. Additional benefit is the discs may easily be lifted when the implement is detached.

The advantages:

- Robust disc coulters, proven design

- Perfect correction on slopes

- Strong reduction of drift

For more information, demo’s, pricing or advice regarding any of our products or services please

Viper 4 Twin

The Viper 4 TWIN is the new top model screen from SBG/Raven. The Viper 4 TWIN is the first tangible result of the acquisition and cooperation of SBG and Raven. Due to the large 12.1” touchscreen, all the functions are easy to control and there is still a really good overview.

Whether it is about tractor steering, TWIN-Implement steering, section control or leveling, all different steering types are fully integrated in to the Viper 4 TWIN. With the Viper 4 TWIN u are able to create and use straight lines, bends, curvatures or contours or a combination of them. The Viper 4 TWIN also has useful features like setting headlands with different widths and displaying the sprayer tracks, possibly with a different working width.

Viper 4 TWIN has numerous additional options such as an extensive crop registration module, capturing height maps and a special module to create trial fields or to plant on a grid. Furthermore, the Viper 4 TWIN has two GPS antenna connections by default. After activation of the second antenna, the Viper 4 TWIN is suitable to simultaneously control a tractor and an implement.

- Viper 4 Twin

- Viper 4 Twin

- Hire Autosteer

For more information, demo’s, pricing or advice regarding any of our products or services please

SBG Trial Field Module

Seeding and planting jobs can now be performed much more quickly, easily and accurately. The SBG Trial Field Module enables the rapid creation of angled headlands, can plot spray paths, fields of the correct length and correct interval spacing with driving paths in both axes.

The intensive and time consuming stake out can be omitted, as the trial field module keeps track of it all for you.

OmniRow®

Our groundbreaking new OmniRow® advanced planter control system is a complete fully integrated system, with RTK sub-inch accuracy and patent-pending planter control technology for the ultimate planting experience.

Total population control

Raven’s OmniRow® advanced planter control system features fully integrated design with RTK sub-inch accuracy and patent-pending planter control technology. This system gives you the power to control seeding rates by row or sections for maximum precision and reliability.

AccuRow™ and Cruizer II™

As an alternative to OmniRow, growers may pair AccuRow™ with Cruizer II™ for simple automatic section control.

Slingshot®-Ready

Use Slingshot RTK/Online Service with OmniRow for seamless data transfer capabilities. Real-time communications and data sharing with any computer anywhere ensure better decisions and more productivity in the field. And Slingshot gives you access to live remote support from Raven’s team of experts.

OmniRow® Multi-Hybrid Control

Patent-pending multi-hybrid control technology combined with variable-rate seeding to deliver maximum yields.

Advanced Planter Control

Soil and land elevation varies across the field, so why not vary the hybrid? Using Raven’s patent-pending OmniRow® Multi-Hybrid Planting control, you can select hybrids based on moisture and disease resistance. The advanced hydraulic-motor clutch provides population control and row shut-off while turn compensation optimizes seed spacing when planting on a curve.

OmniRow Multi-Hybrid is also the recipient of an AE50 award celebrating product innovations in agriculture, food, and biological systems.

AccuBoom™

AccuBoom’s automatic section control capability is your best protection against rising input costs, thanks to greater fuel and chemical savings, faster spraying times, and more accurate spraying. It’s easy to set up and operate with Raven and third-party spray consoles and works with 99% of the self propelled and pull-type sprayers on the market. Now available with Raven’s optional hand-held remote for checking sections.

Simple section control pays for itself

Greater fuel and chemical savings, faster spraying times, ease-of-operation and more accurate spraying all add up quickly to improve your return on investment each and every season. Dollar for dollar, AccuBoom™ offers the fastest paybck in precision ag equipment. AccuBoom™ automatic section control is your best protection against rising input costs.

With a wireless receiver and remote control option, you can check each section by yourself outside the cab. This handy accessory saves time and fuss and lets you turn each boom section on and off while you’re standing right there to see.

For more information, demo’s, pricing or advice regarding any of our products or services please

AutoBoom®

Raven’s AutoBoom® automatic boom height control systems are like money in the bank, giving you faster operating speeds, simple installation and user-friendly controls. AutoBoom’s unique hydraulic-powered design delivers a smooth, more responsive height-adjusting system for spraying perfection. With three systems to choose from for pre- and post-emergent applications, you can be sure we have the boom for you.

Automatic and effortless boom height control

The AutoBoom® automatic boom height control system offers faster operating speeds, simple calibration and user-friendly controls. Its unique hydraulic-powered design delivers a smooth and responsive height-adjusting system. With three options to choose from, there’s an AutoBoom® that’s just right for you.

AUTOBOOM POWERGLIDE PLUS SYSTEM

Upgraded with a cushioned wheel for enhanced performance in extreme field conditions. PowerGuide Plus also includes a complete system upgrade with CANbus, making it a snap to use with any Raven field computer. Ideal for pre-emergent applications, this system is upgradable to UltraGlide via a simple-to-install upgrade kit.

- State-of-the-art hydraulics maintain a constant pressure

- Simplified one-touch calibration

- Compatible with many consoles

AUTOBOOM ULTRAGLIDE SYSTEM

Take advantage of ultrasonic sensors that gauge the distance to the ground with this fully-loaded boom height control system that’s ideal for pre- and post-emergence applications. UltraGlide includes a center rack control that makes it easy—and quick—to return to spray and transport modes. CANbus technology for integrated multi-system operations is also standard.

- In-cab monitoring and adjustments

- Simplified one-touch calibration

- Five sensor capability

- Wheel-mode capability

- Compatible with many consoles

AUTOBOOM ULTRAGLIDE WITH POWERGLIDE PLUS

The ultimate upgrade offers the best of both AutoBoom PowerGlide and AutoBoom UltraGlide systems.

- Autoboom

For more information, demo’s, pricing or advice regarding any of our products or services please

SmartYield™ Pro

Data from start to finish

Dealers installing their first SmartYield™ Pro systems were amazed at the ease and speed at which an installation could be completed. The system was extensively tested on over 40,000 acres of all major crops with accuracies often exceeding 97%.

Producers who tested SmartYield™ Pro side by side against factory installed force-plate technology consistently commented on ease of calibration and spatial accuracy of SmartYield™ Pro. Data analysis post-harvest is validating these comments with most customers preferring to use their Raven yield data vs the yield data generated by their factory installed equipment.

Watch SmartYield™ Pro in action and see it to believe it.

Slingshot®-Ready

When you use the revolutionary Slingshot RTK/Online Service with SmartYield™ Pro, you have access to seamless data transfer capabilities. Real-time communications and data sharing with any computer anywhere ensure better decisions and more productivity in the field. And Slingshot gives you access to live remote support from Raven’s team of experts.

For more information, demo’s, pricing or advice regarding any of our products or services please

Slingshot

Advanced precision

Raven has propelled precision ag to an entirely new level with this innovative product. Slingshot combines wireless connectivity with robust online tools and top-shelf precision ag hardware to upgrade your level of control and efficiency.

Slingshot Field Hub

Designed to work with major cellular networks in North America and around the world, the Slingshot Field Hub serves up high-speed Internet on your field computers. You can also connect devices like phones and tablet computers to Wi-Fi enabled versions of the Field Hub.

Slingshot RTK

The Slingshot Field Hub allows you to access Slingshot’s advanced RTK correction signals, or those provided by third-party providers, such as CORS networks. Slingshot’s cellular-based RTK enables you to operate without worrying about line of site limitations characteristic of radio-based RTK. You can provide RTK coverage for up to 1.8 million acres with a single Slingshot Base Station.

Slingshot GS

Slingshot GS is a new cellular-delivered correction service with decimeter accuracy, without the need for a local reference station. You can even leverage your existing Slingshot Field Hub and Raven GPS hardware to access Slingshot GS.

Slingshot Online

Store your job data from Raven field computers in your secure Slingshot database that you can access anytime, anywhere with a simple Web browser. Observe your fleet and manage operations with any laptop, desktop or mobile computer from anywhere in the world. With a free Slingshot account, you can track equipment locations, dispatch prescription maps, and monitor, collect and analyze job data from Raven field computers.

- Slingshot

For more information, demo’s, pricing or advice regarding any of our products or services please